Energy efficiency improvement in existing contexts of the metal processing industry

The ETA research project is entering its second round. Previous investigations in industrial projects at the Institute for Production Management, Technology and Machine Tools at the Technical University of Darmstadt (PTW) show that significant energy saving potentials can be raised by transferring energy efficiency measures to existing industrial plants - between 25 and 40 % of the total energy demand, depending on the application and system limit. Against this background, solutions are to be developed in the joint project "ETA in Existing Contexts" that will enable energy efficiency technologies to be disseminated quickly, comprehensively and economically in the German industrial landscape.

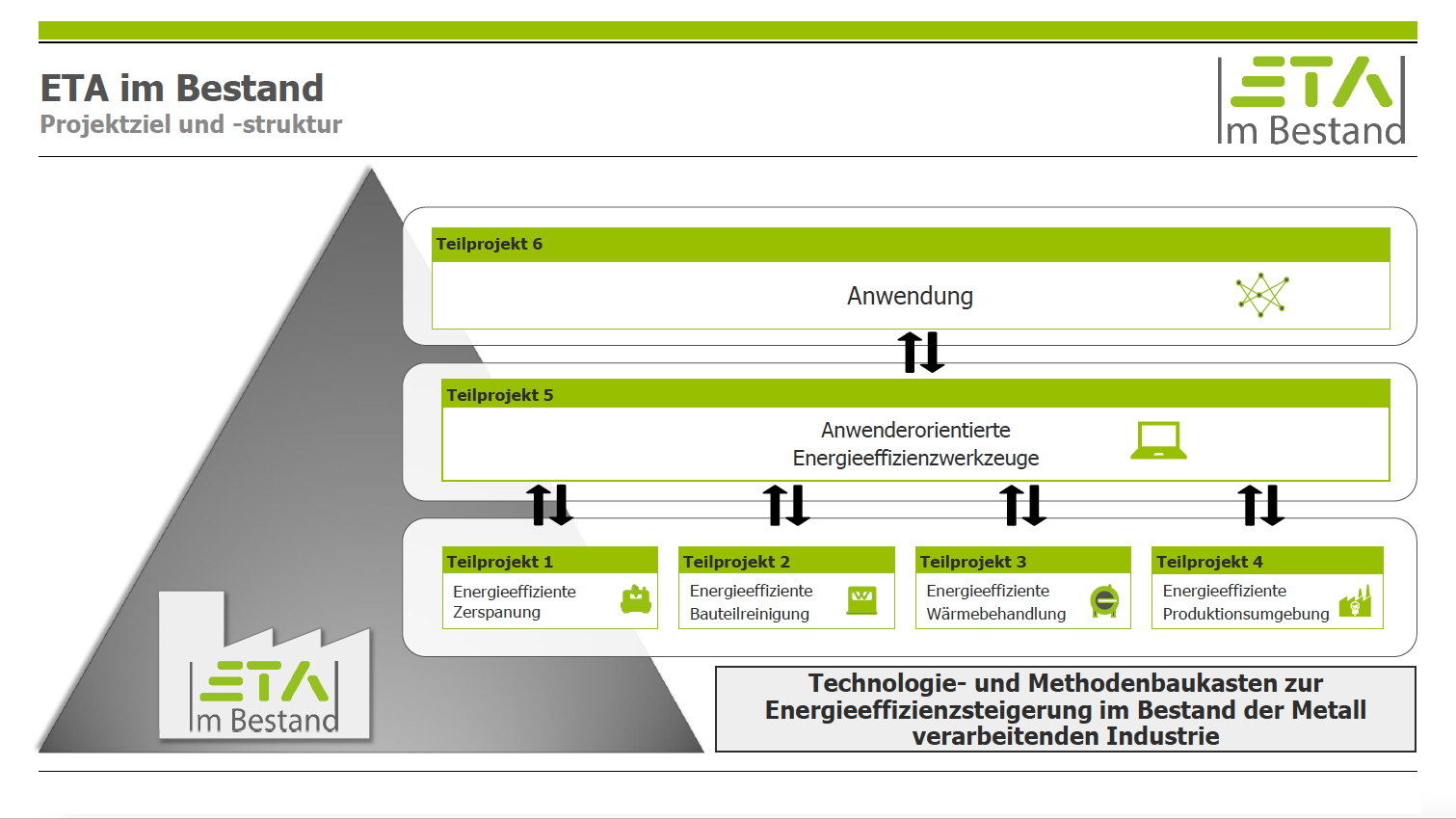

The project is divided into six networked subprojects (see project structure). In subprojects 1-3, energy efficiency improvements are being developed at the level of the production machines. In subproject 4, a typification of existing industrial buildings and possible energy-related renovation measures, the investigation of building-side air conditioning and waste heat utilization concepts, and the development and testing of modular building supply and air conditioning components are planned. Subproject 5 plays a central role in the networking of all topics. The content is the development of user-oriented energy efficiency tools to support the technical planning of energy efficiency measures. In subproject 6, the tools developed will be applied using real case studies from industry and the ETA factory research demonstrator.

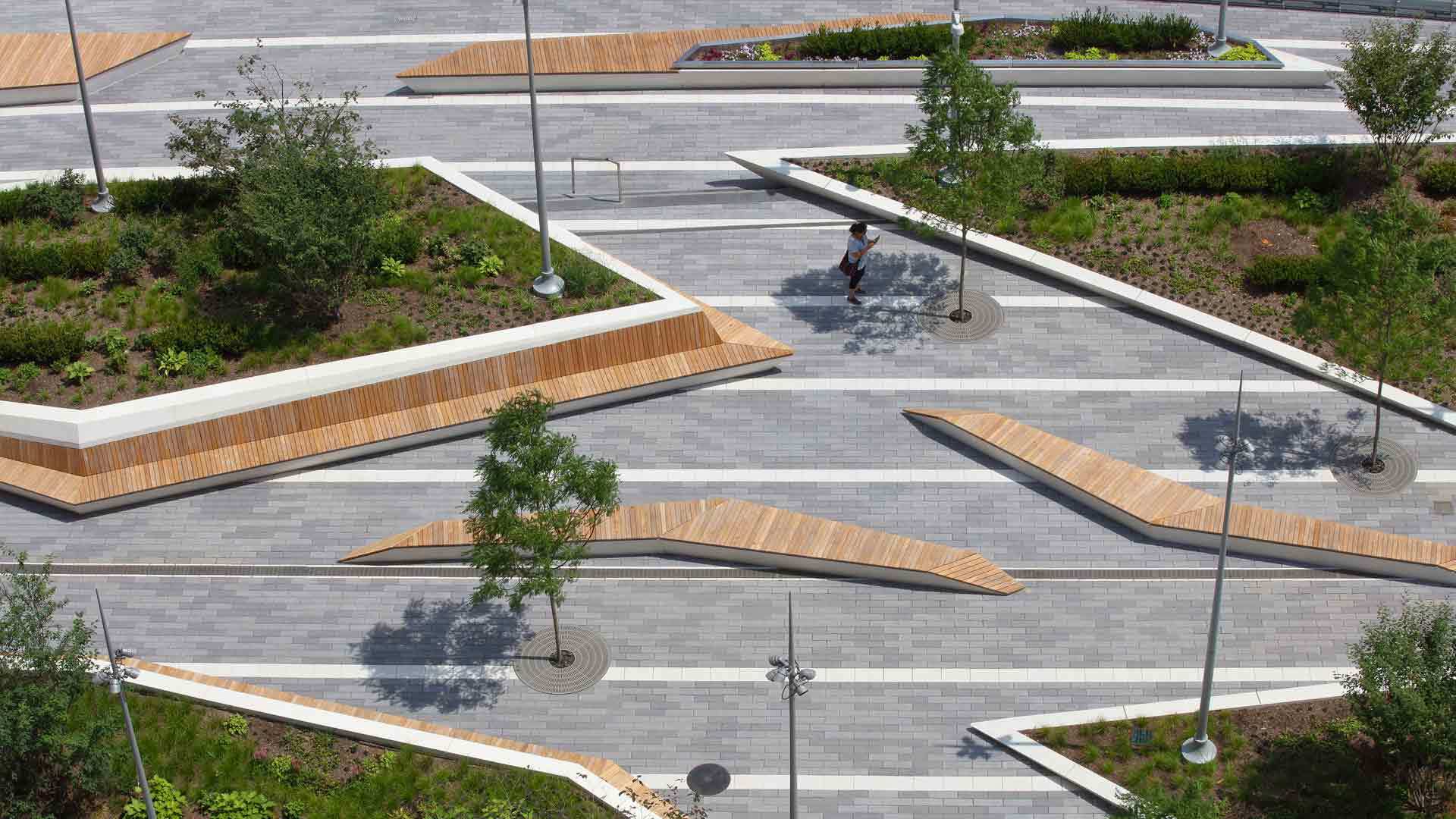

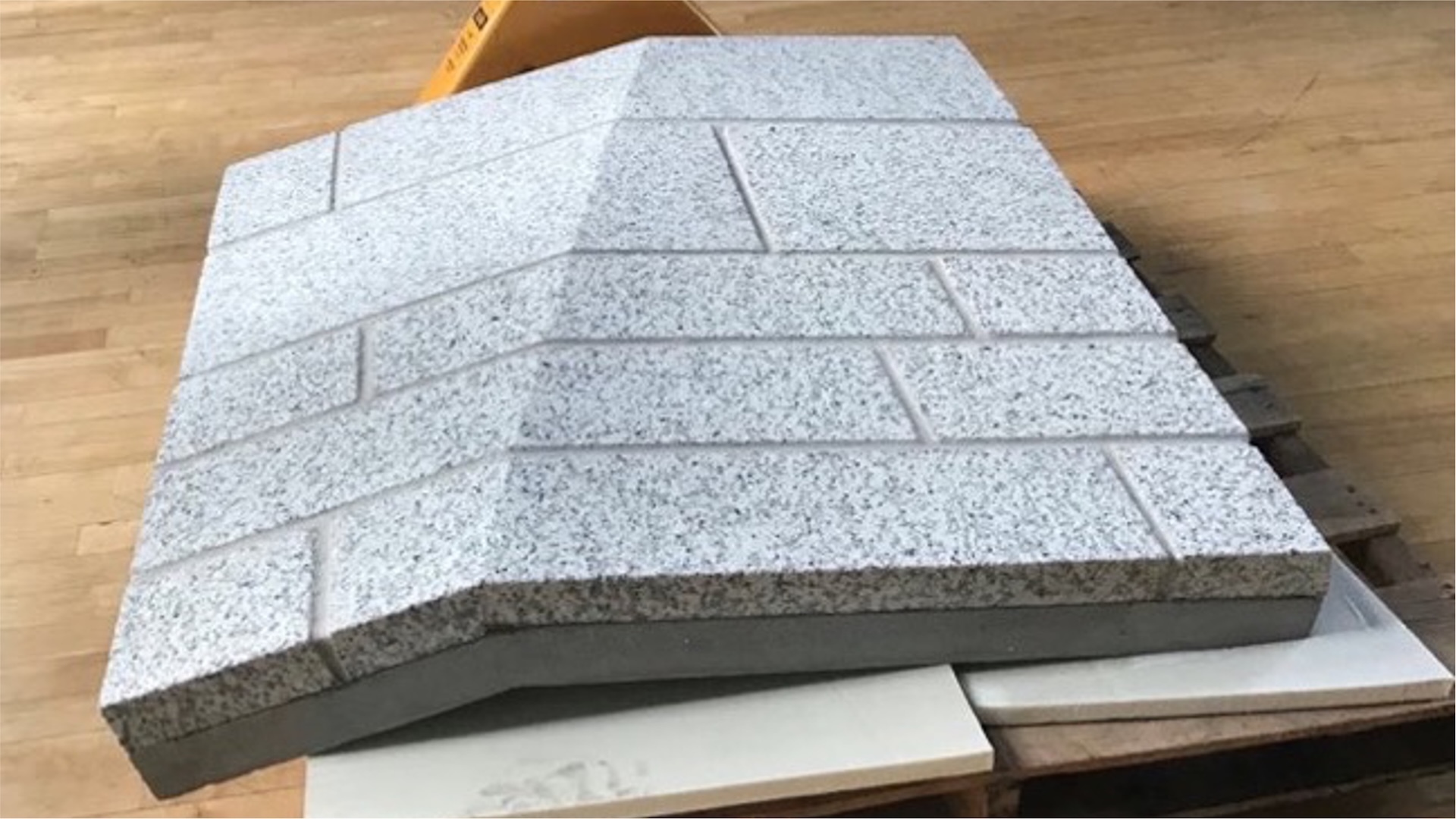

DUCON is involved in sub-project 4, which aims to enclose individual machines with thin, thermally activated concrete elements, similar to the façade panels of the ETA factory, in order to use and dissipate the waste heat from the machines.

The project started in November 2020 with a planned duration of three years. Funding (funding code: 03EN2045A-I) is provided by the German Federal Ministry for Economic Affairs and Energy (BMWi) as part of the German government's seventh energy research program. The project is supervised by the Project Management Jülich (PTJ).