Thermally activated facade panels

The thermal activation of DUCON panels through the installation of capillary tube mats in the existing micro-reinforcement gives DUCON technology another interdisciplinary property. This transforms DUCON panels from a passive to an active component of energy management.

This innovative feature is already being exploited by the unique ETA Factory (ETA = Energy Efficiency, Technology, and Application Center) research project at TU Darmstadt. The research project is investigating representative metal processing production facilities from an energy efficiency perspective. In addition to improving the energy efficiency of the individual production facilities, the primary goal is to network the machine peripherals, building services, and building envelope in order to enable further savings potential and efficiencies.

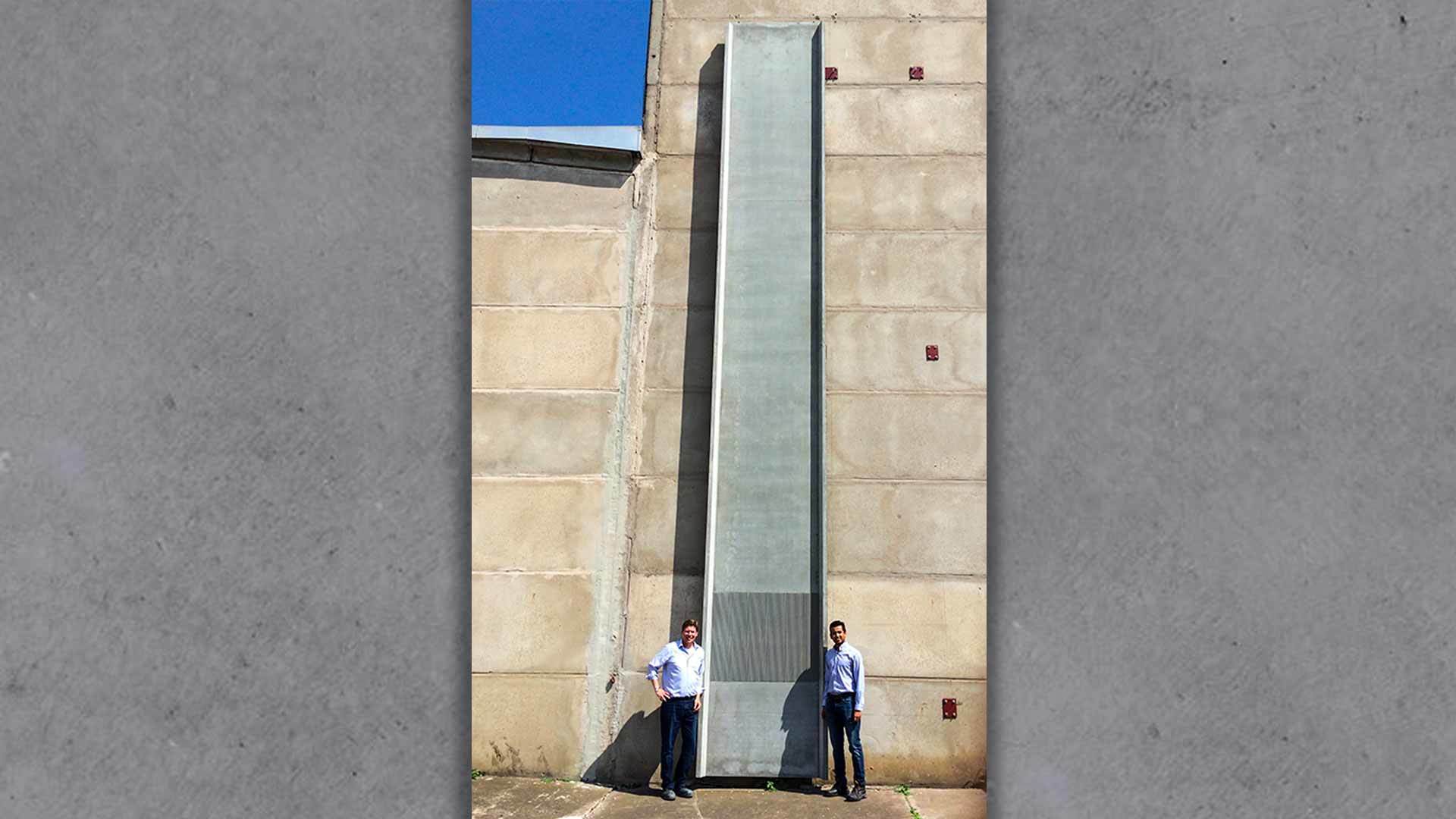

The outer shell of the ETA factory is made of 11 m (36 ft) long and 5.5 cm (2.2 in) thin DUCON panels with thermal activation. Thanks to the good thermal conductivity and high heat storage capacity of concrete, the DUCON panels are suitable for use as effective cooling surfaces for machine cooling in winter and, when wetted with collected rainwater and subsequently evaporated, also in summer.

With the evaporation effect, a cooling capacity of 386.4 kWh (with 280 m² of activated surface area; between 6:00 a.m. and 6:00 p.m.) was achieved on summer days with a maximum daily temperature of 33 °C (91 °F) and a temperature level of the supplied heat transfer medium of 40 °C (104 °F). During the night, the cooling capacity was 537.6 kWh. This covers the daily cooling requirements of the production facilities of approx. 100 kWh many times over. In the transition periods, the DUCON panels serve as solid absorbers to support the heating system. In this form, DUCON panels make an active contribution to interdisciplinary energy management.

The ETA-factory including the energy efficient building envelope out of DUCON has been awarded for the following prizes:

- German Design Award 2018

- Iconic Award 2017

- Bundespreis Eco-Design 2017

- Land der Ideen 2017

- Detail Produkt Preis 2017

- Heinze Architectural Award 2017

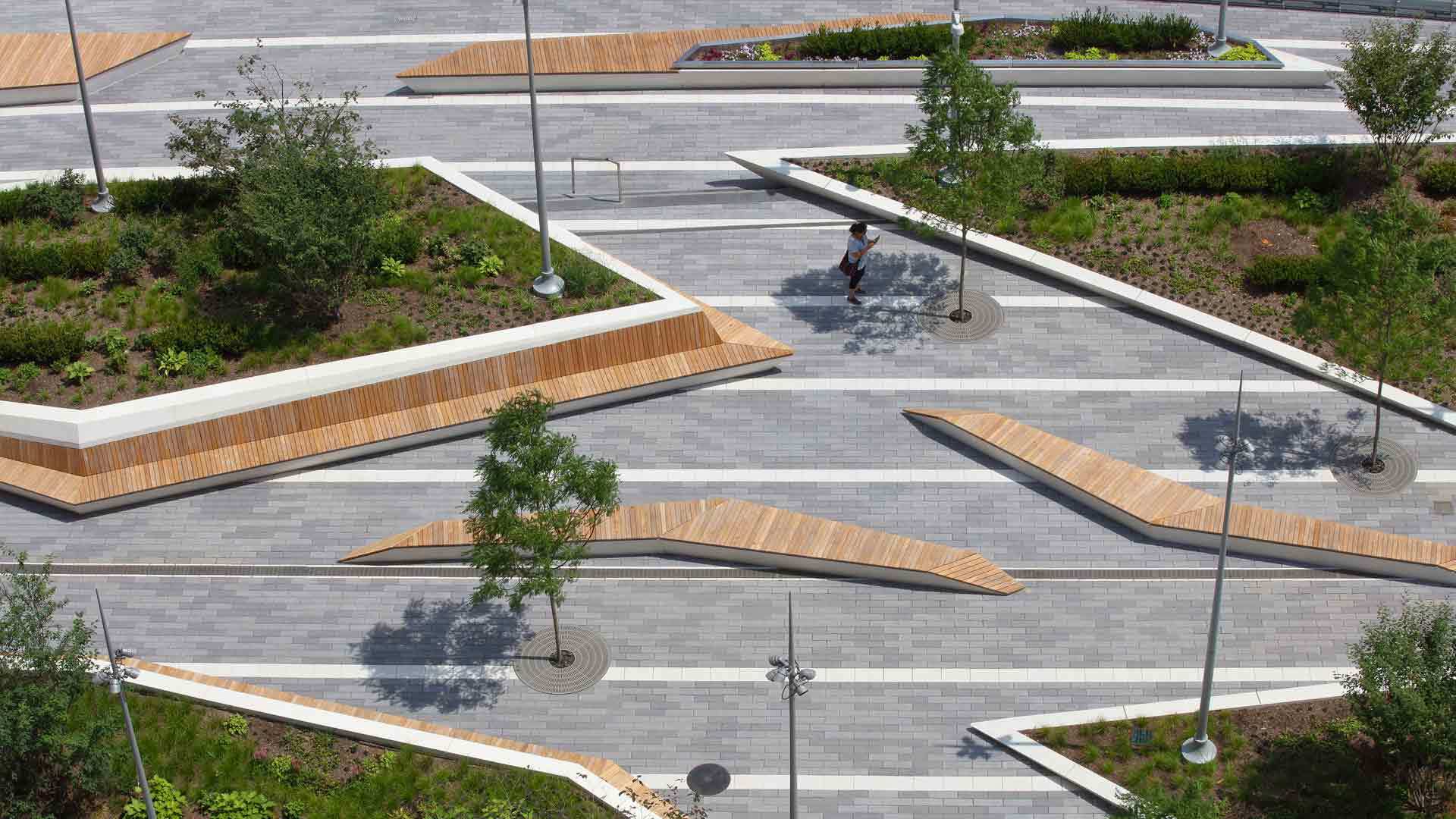

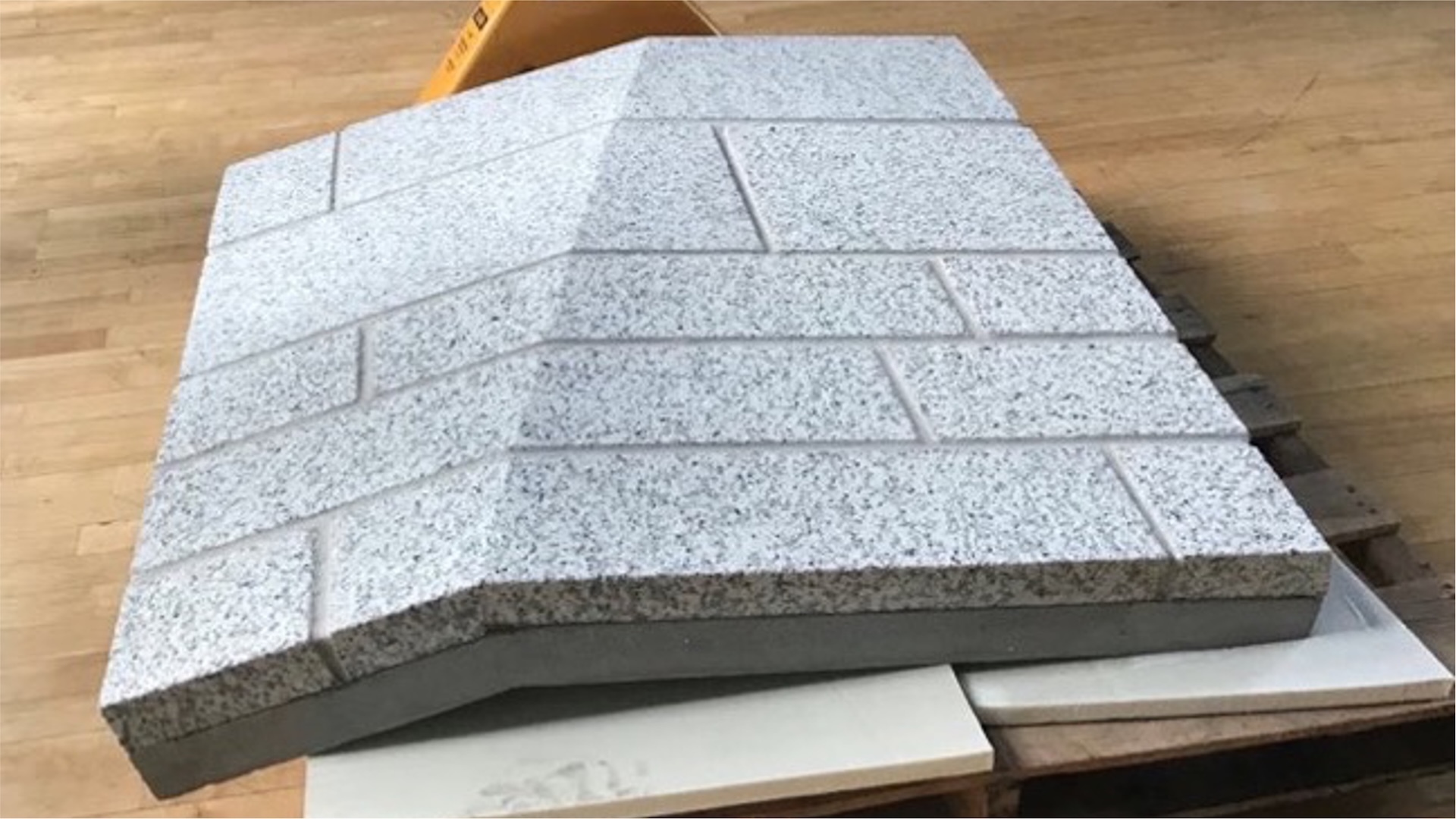

Further examples of DUCON Architectural applications

Feel free to contact us!

If you have further questions about DUCON Technology, we will gladly answer them by phone or email.

Germany & Europe

T +49 6151 30724-0

info@ducon.eu

North America

Phone: +1-212-498-7111

info@ducon-usa.com