The outstanding features of DUCON technology at a glance

The strengths of DUCON are wide-ranging and are used in a wide variety of areas. The highlights of the technology are summarized here:

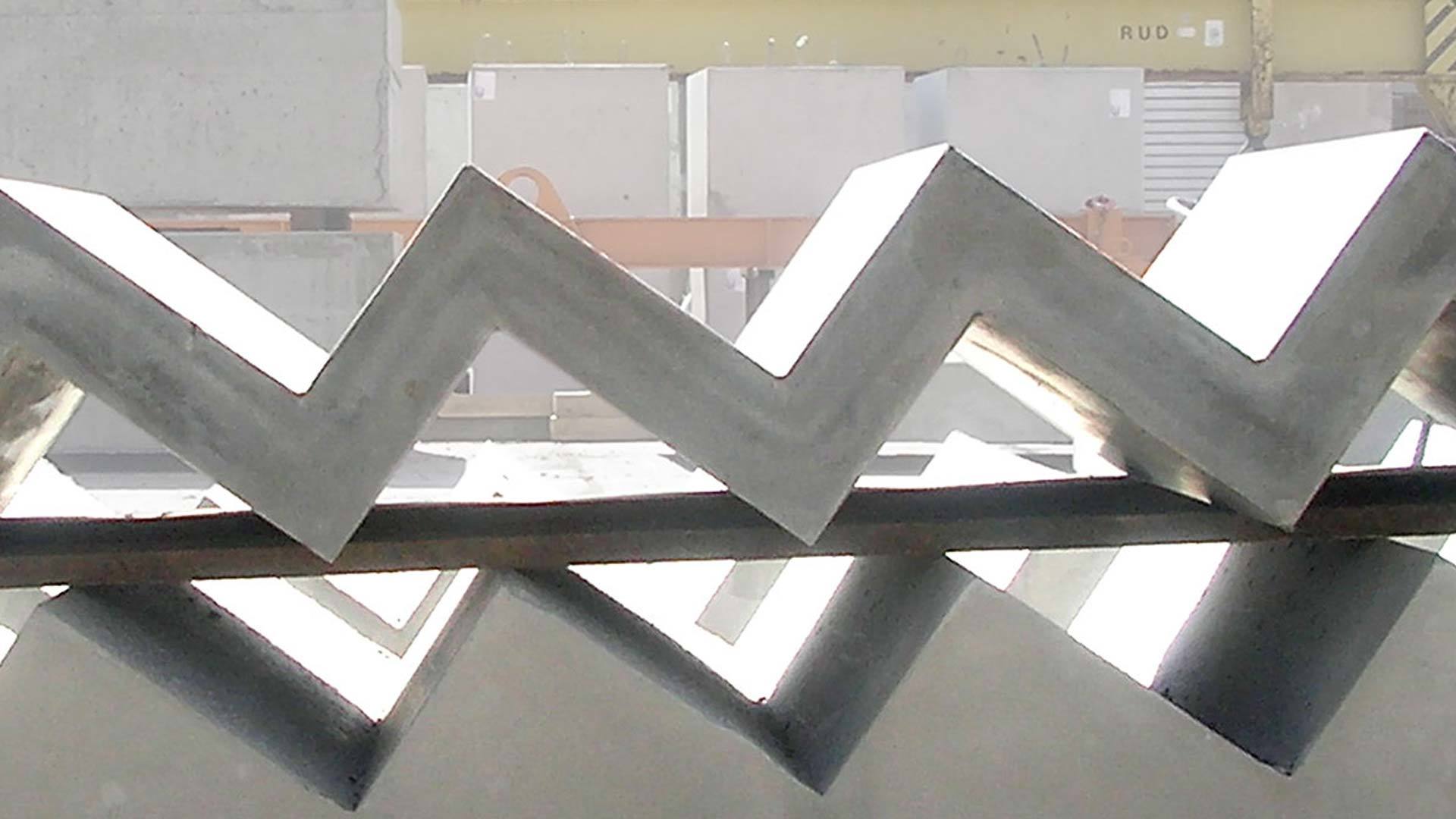

Thinnest self-supporting concrete staircase (folding staircase 8 cm)

DUCON offers the thinnest solution for concrete stairs. In contrast to conventional reinforced concrete, a continuous slab can be eliminated, creating a folded structure. In this way, storey-high stairs can be constructed with a component thickness of just 10-12 cm, and shorter flights of stairs with just 4-8 cm.

Thinnest roof shell "Parapluie", 25-30 mm thin (Tsuboi Award 2013)

The "Parapluie" (umbrella) roof shell construction is a demonstration of the efficiency of DUCON technology. With a component thickness of just 25-30 mm, the component is able to withstand a load of several hundred kilograms. DUCON received the Tsuboi Award for the prototype in 2013.

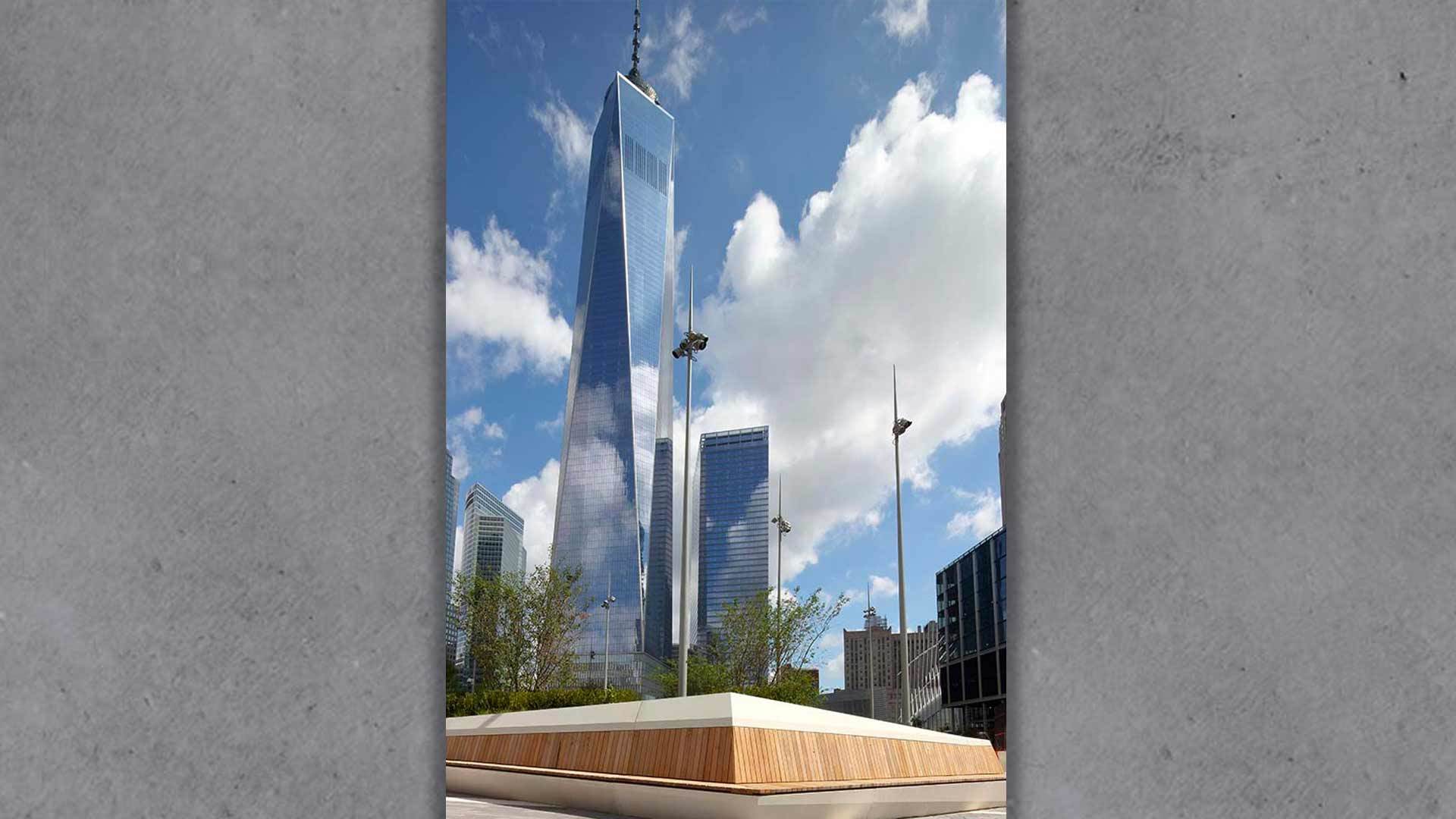

Thinnest solution for blast protection (World Trade Center)

DUCON is the thinnest solution for protection against explosions. Compared to conventional reinforced concrete, the required thickness can be reduced to less than half. The system has made it across the Atlantic to the USA, where critical areas of the World Trade Center are protected by DUCON.

Sealing layers & ceiling reinforcements (30-55 mm thin, 15,000 m2 jointless)

DUCON can be applied as a thin layer of just a few centimetres to restore damaged or insufficiently load-bearing existing surfaces. The DUCON layer can be applied seamlessly over existing cracks.

An impressive example of this is the design of an area of over 15,000 m2 in Stuttgart, which was completed without any high-maintenance joints.

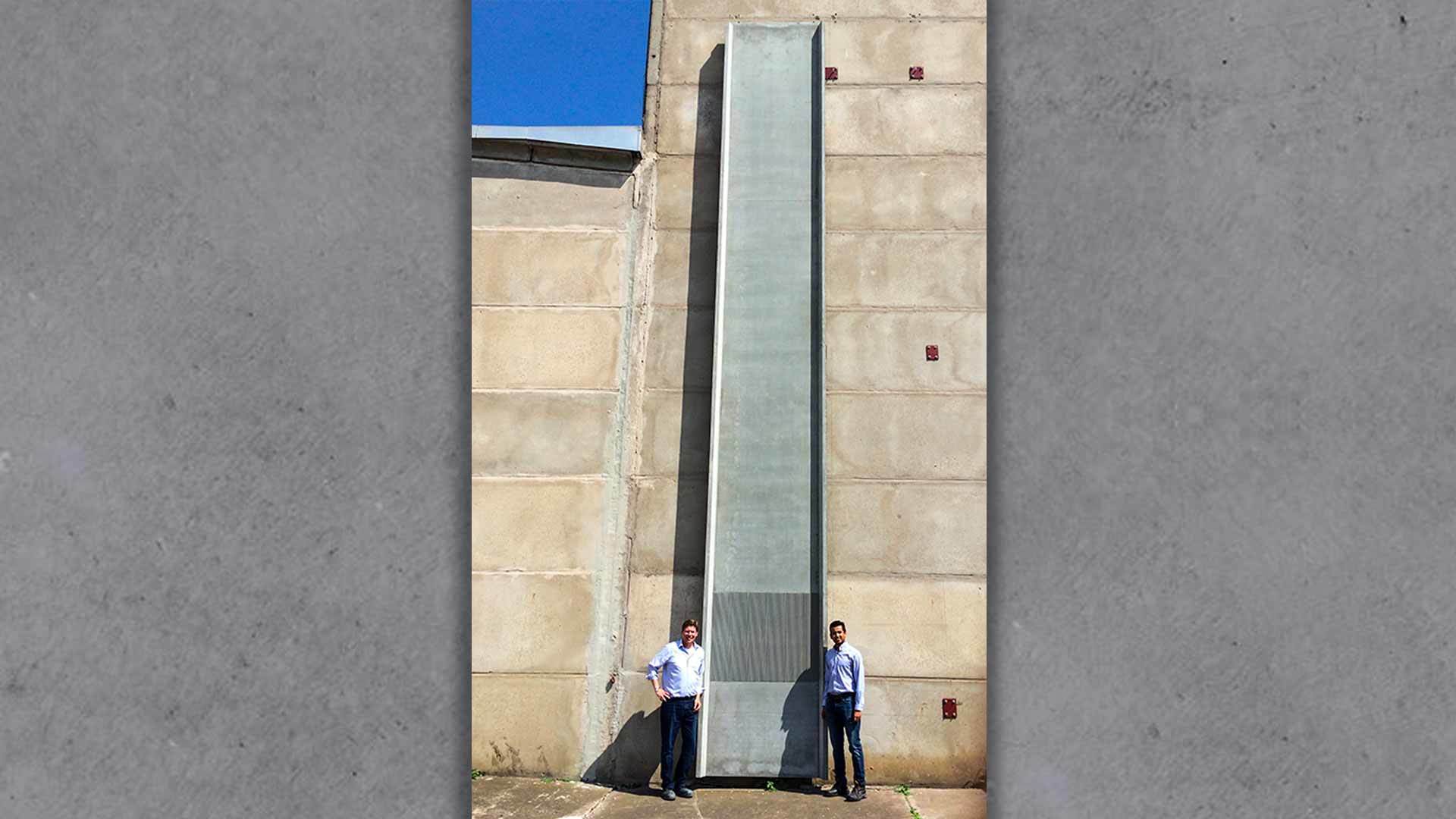

Thermally activated energy facades (L = 11 m, 50 mm thin)

With thermally activated components, DUCON offers an innovative way of regulating the temperature in production buildings, for example, via the façade. Capillary tube mats are installed in prefabricated parts for this purpose. These dissipate the excess heat to the outside via passive cooling.

This system was used in the ETA factory at Darmstadt Technical University. By activating the roof panels and parts of the façade panels, the heat generated by the machines inside can be dissipated passively, meaning that no further air conditioning is required. The capillary tube mats were installed in panels just 50 mm thick and up to 11 m long.

"House in the vineyard", all components 30 mm thin (Rhineland-Palatinate Innovation Award 2013)

Together with the Technical University of Kaiserslautern, DUCON developed the "House in the Vineyard" as a demonstration object. The special feature of the construction: the panels, which are up to 6 m long and only 30 mm thick, were inserted into each other using a tongue and groove system without additional dowel connections. The project was awarded the Rhineland-Palatinate Innovation Prize.

Feel free to contact us!

If you have further questions about DUCON Technology, we will gladly answer them by phone or email.

Germany & Europe

T +49 6151 30724-0

info@ducon.eu

North America

Phone: +1-212-498-7111

info@ducon-usa.com