DUCON concrete - the more climate-friendly concrete.

Concrete is the most important building material of our time. Around 30,000,000 tons are used worldwide every year. Only with it can modern architecture be realized in its current form. It offers a wide range of possibilities for breathtaking bridges, houses, skyscrapers, roof structures and floor surfaces, as well as for industrial buildings. The problem: Concrete is not considered a particularly environmentally friendly building material, primarily because of its energy-intensive production.

The solution: DUCON concrete - the more climate-friendly concrete available immediately.

In contrast to conventional reinforced concrete, DUCON concrete offers the possibility of a significantly smaller component volume due to its composition. In addition, components can be made significantly lighter with the same strength.

DUCON house in the vineyard 30mm thin

The result:

- lower material usage of steel, cement, sand and gravel

- less transport and installation effort

- slimmer substructures

- greater durability

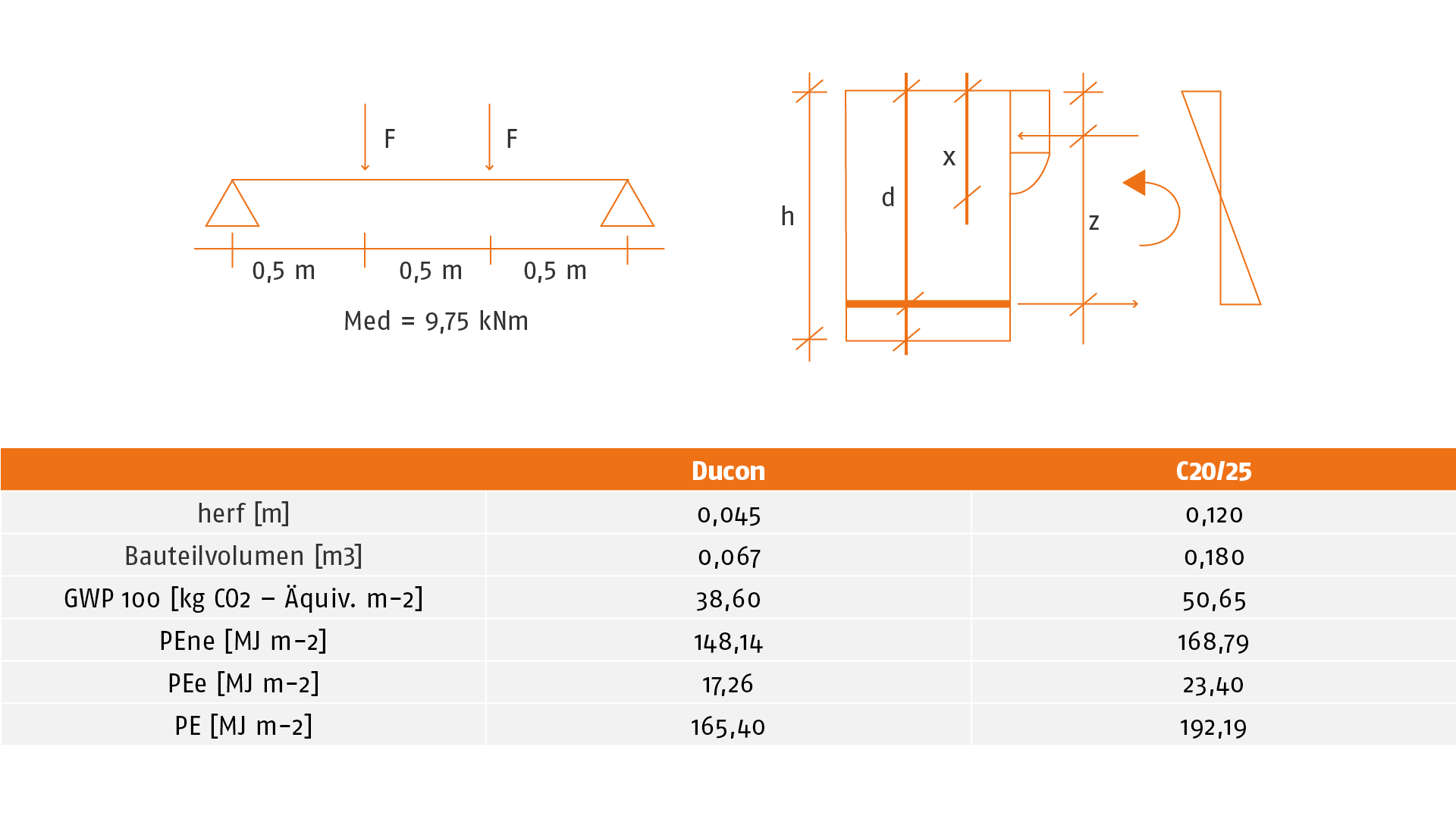

Comparison of DUCON and C20/25 in 4-point bending test

Comparison of component volumes of DUCON and C20/25 in 4-point bending test

DUCON concrete has a significantly lower component volume and thus a significantly lower weight with at least the same performance as reinforced concrete.

Another advantage: components made of DUCON concrete are recyclable and can thus be easily processed into high-quality recycled concrete with compressive strength C35/45 and consistency class F2.

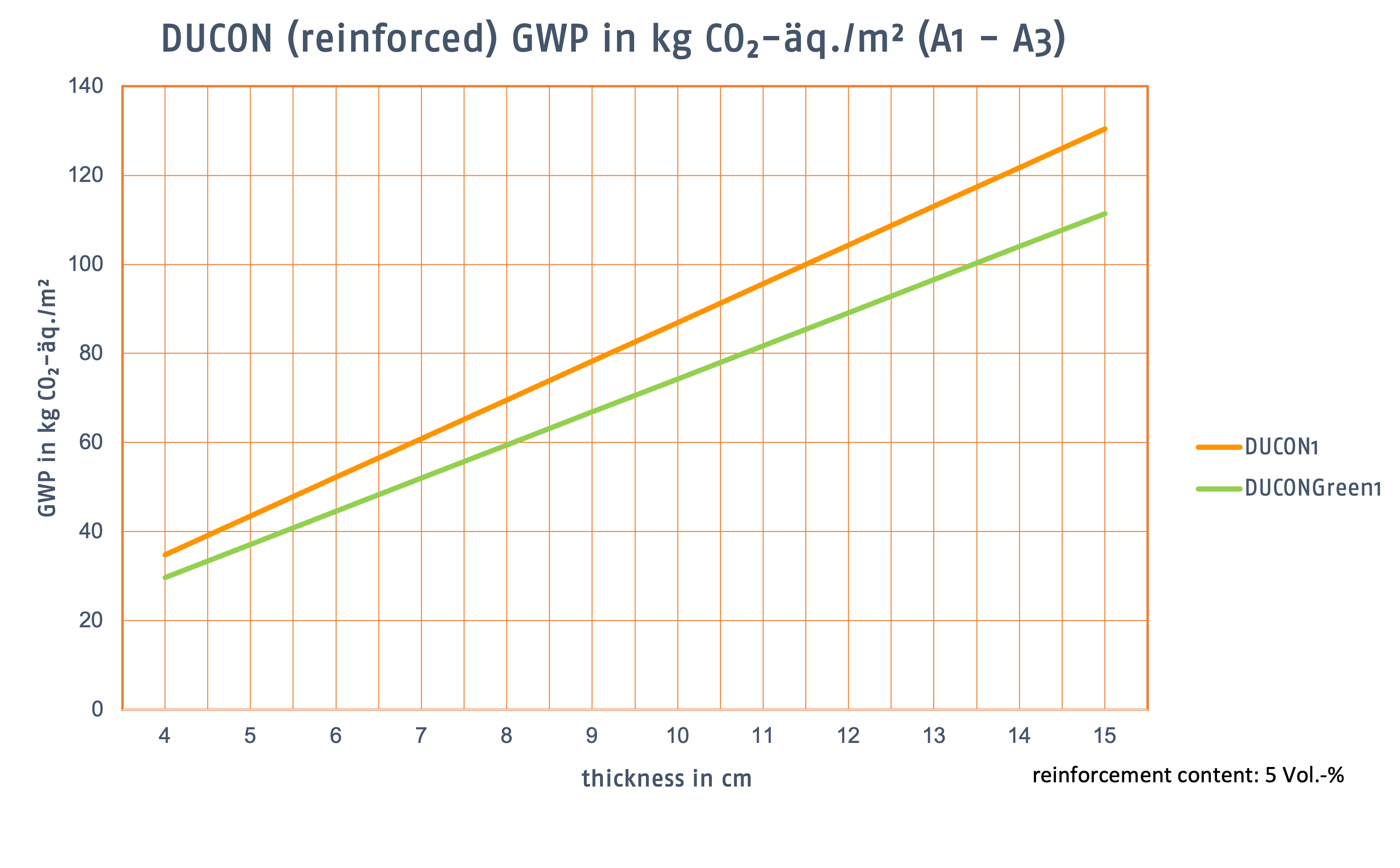

Global Warming Potential (GWP) DUCON incl. reinforcement

The following diagram shows the Global Warming Potential (GWP) measured in kg CO₂ equivalent per m² for the product stage (Cradle to Gate / A1-A3) of our reinforced high-performance material DUCON and the ecologically optimized variant DUCONGreen1 in relation to the component thickness. In A1-A3 the raw material supply, including processing of secondary material input, the transport of raw material and secondary material to the manufacturer and manufacture of the construction product, and all upstream processes from cradle to gate are considered.

The data is based on company-internal primary data and generic data from the ecoinvent database version 3.11.

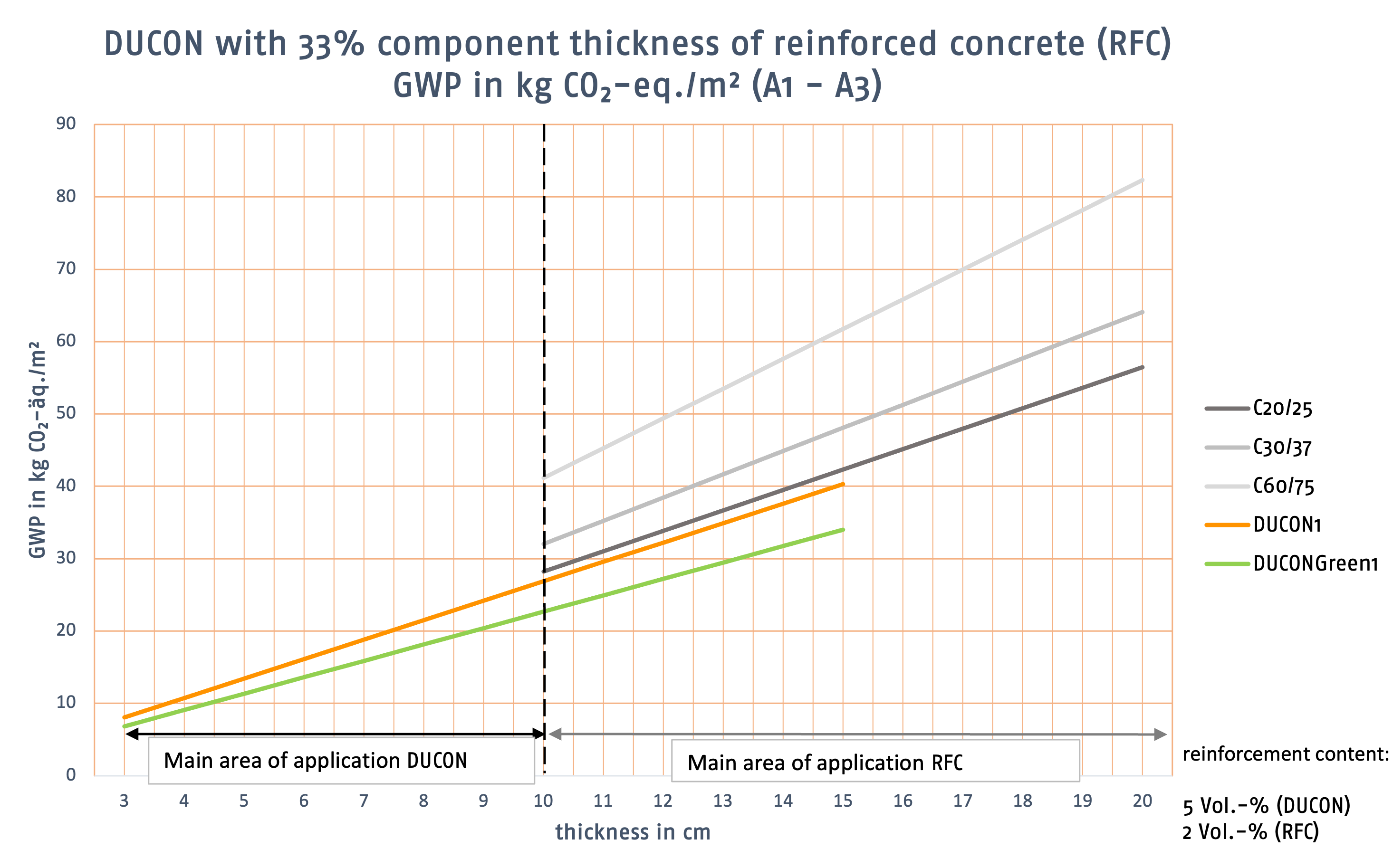

In comparison to steel reinforced concrete

DUCON achieves the same load-bearing capacity (e.g. façades) with only 33% of the component thickness of steel reinforced concrete. The influence on the GWP is illustrated in the following diagram.

The data is based on company-internal primary data and generic data from the ecoinvent database version 3.11. The EPD NEPD-10122-10122-2 applies to DUCON1. For reinforced concrete, the EPDs of InformationsZentrum Beton GmbH were used for the corresponding compressive strength classes. These can be viewed on the website of Institut Bauen und Umwelt e.V. (IBU). A reinforcement content of 2% by volume was used for the reinforced concrete.

In the spirit of circular economy

We also strive to achieve the highest possible recycling rate for our technology in the interests of circular economy. To this end, recycling tests were carried out with our micro-reinforced test specimens using a mobile crushing plant. The recycling process can be seen in the following video.

The output of the recycling process using a mobile crushing plant shows that DUCON® can be separated almost 100% into concrete and reinforcement. The fine fraction of the old concrete mortar can be reintroduced into the company's own product cycle. The other parts can be reused for alternative applications. This reduces the further extraction of primary resources and thus protects the environment.

EPDs - UHPC DUCON1

Our UHPC DUCON1 has a verified EPD as ready-mixed concrete and as a binder, which can be viewed via the following links.

Feel free to contact us!

If you have further questions about DUCON Technology, we will gladly answer them by phone or email.

Germany & Europe

T +49 6151 30724-0

info@ducon.eu

North America

Phone: +1-212-498-7111

info@ducon-usa.com