Refurbishment of a drainage area at the Bamberg waste incineration plant

As part of a comprehensive refurbishment of the Bamberg waste incineration plant, the floor slab of the "slag bunker" was also sealed with a 55 mm (2.2 in) thin layer in compliance with the German Water Resources Act (WHG). The so-called slag bunker is a drainage area that temporarily serves as a collection area for incineration residues. These residues, which are cooled to 50 °C beforehand, are first poured onto the surface and then distributed by a grab crane onto trucks for removal. Some of the liquid components that run off via the floor surface into filter basins are classified as hazardous to groundwater. In this case, DUCON offers an approved WHG sealing layer with a very high resistance to mechanical stress.

An important aspect in the execution was the time factor. As the waste incineration plant had to resume operations quickly, there was only a time window of 2.5 days available for execution.

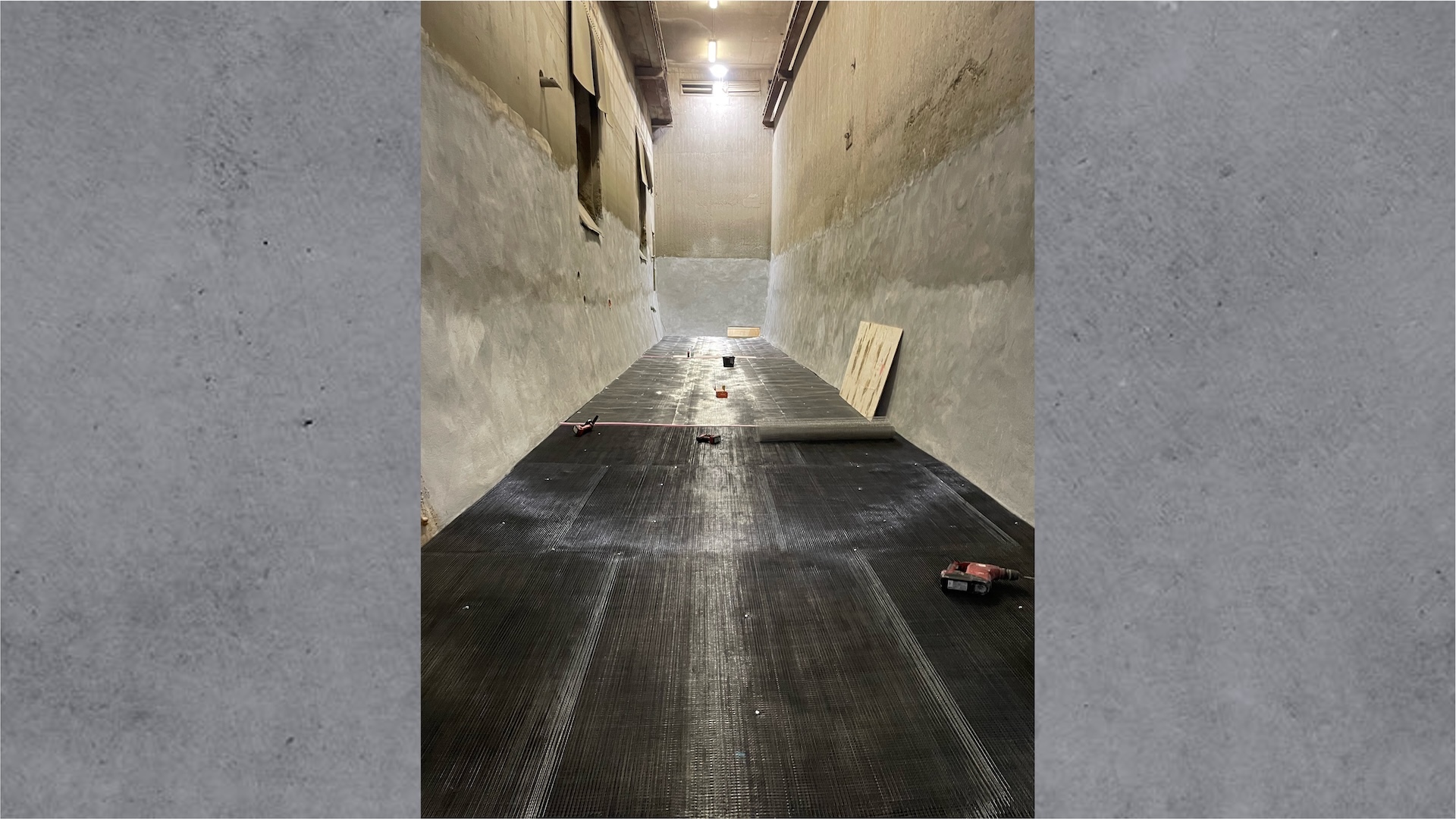

DUCON traveled to Bamberg with its own team to carry out the work. After a brief survey and coordination with the company and the construction companies working on site, the reinforcement work could begin on Thursday morning. After just a short time, the 21 layers of reinforcement for the first of the three sections were laid out and bolted to the substructure. The micro-reinforcement was also installed in the other two sections within a few hours, so that the reinforcement work on the 100 m2 (1,100 ft2) area could be completed in the afternoon.

On Friday morning, the day began at a local ready-mix concrete plant. The DUCON concrete was mixed here and then transported to the construction site. It was adjusted to the correct consistency under the supervision of DUCON. Due to the gradient of the surface, the concrete had to have a certain stiffness, but still be flowable enough to flow through all the reinforcement layers. Once the first truck mixer had driven down the steep ramp to the surface, paving could begin. Shortly after midday, the entire surface was concreted and the curing process could begin.

Thanks to the low material consumption, the simple installation of the system and the high early strength of the DUCON mortar, operations at the waste incineration plant could be resumed the following Monday, just four days after the start of work. For the customer, this meant minimal downtime and therefore a highly cost-effective solution.