Life Cycle Assessment (LCA) is regulated by ISO 14040 and ISO 14044. An LCA is used to determine the environmental impact of a product system under consideration.

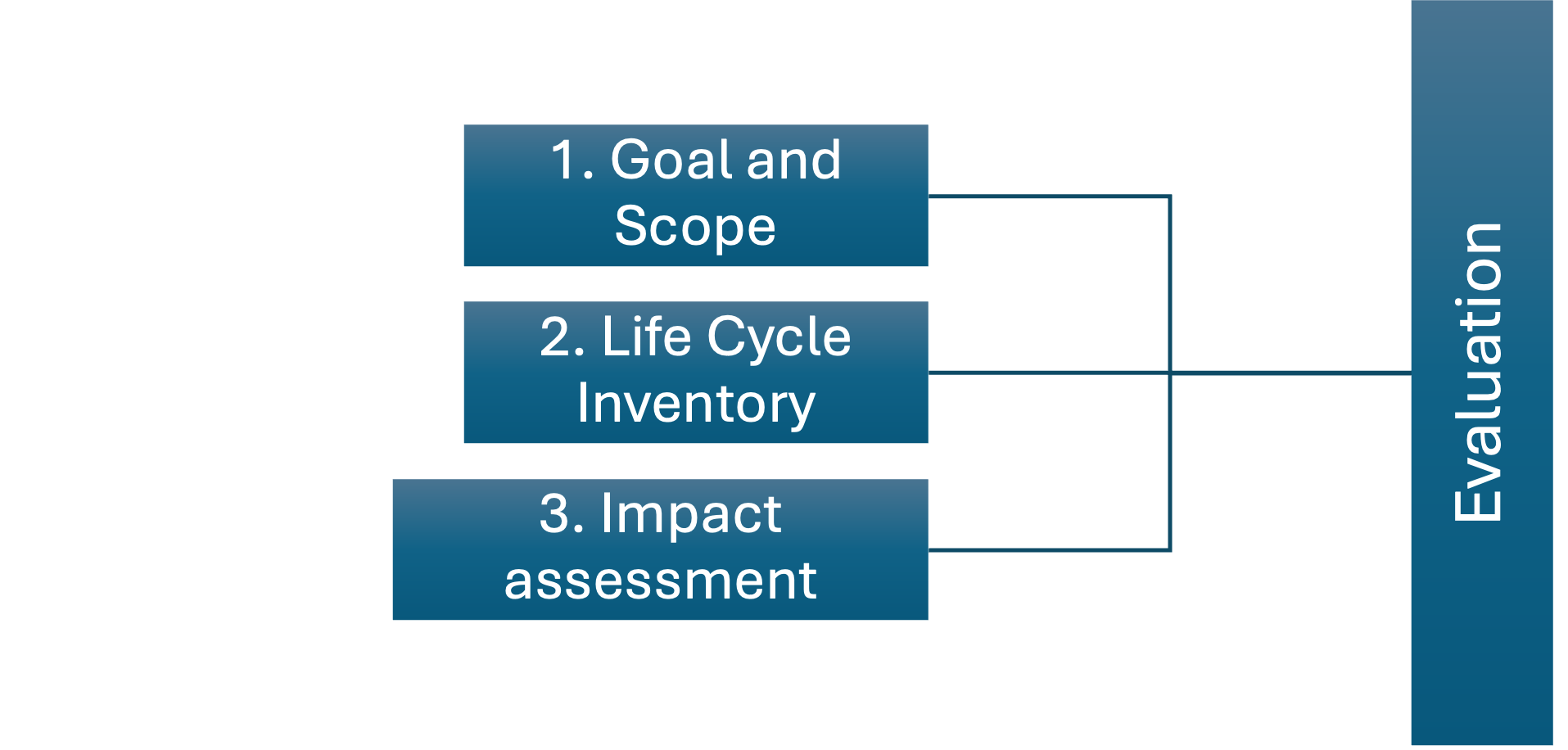

The LCA can be divided into the following four steps:

The objective and scope of the investigation serve the purpose of the LCA study and the limitation of the product system by means of cut-off criteria to the main influencing factors with regard to a defined functional unit. The life cycle inventory comprises the data collection of the relevant processes from inputs, outputs, elementary flows and material and energy flows. Data can be collected using primary data, secondary data, generic data or EPDs. Data is then calculated for the product system in question and possible allocations are applied. In the impact assessment, the life cycle inventory results are linked to corresponding impact categories, impact indicators and characterization models. The results of this are, for example, the GWP100 or the primary energy demand in relation to the functional unit. The final evaluation is used to interpret the results and draw up optimization approaches.

The following can be stated in relation to DUCON®:

The life cycle assessment of DUCON® mortar is based on the functional unit 1m³. The impact assessment results in a GWP100 of DUCON® at 618.64 kg CO2-eqv/m³. This is significantly influenced by the CEM I 52.5 R in the cement compound. Cement is also the largest energy consumer in terms of primary energy demand, which amounts to a total PEges of 3417.16 MJ/m³. At 439.14 MJ/m³, the share of renewable energy demand PEern only amounts to around 12 % of the total energy demand. The conclusion from this is that the key to a further improvement in the life cycle assessment will be the reduction or substitution of the cement compound or a CO2-free production of cement.

To this end, DUCON has been working on an ecologically optimized alternative to the existing DUCON®. By adapting the mix design, which is largely characterized by the substitution of CEM I with blast furnace cement (CEM III), both the greenhouse gas potential can be reduced by up to 52% and the total primary energy requirement by up to 37% compared to DUCON®. You can find more information on our website under the heading “Sustainability”.