DUCON40 as a 32,200 m² Jointless Load-Bearing and Sealing Layer in Battery Center

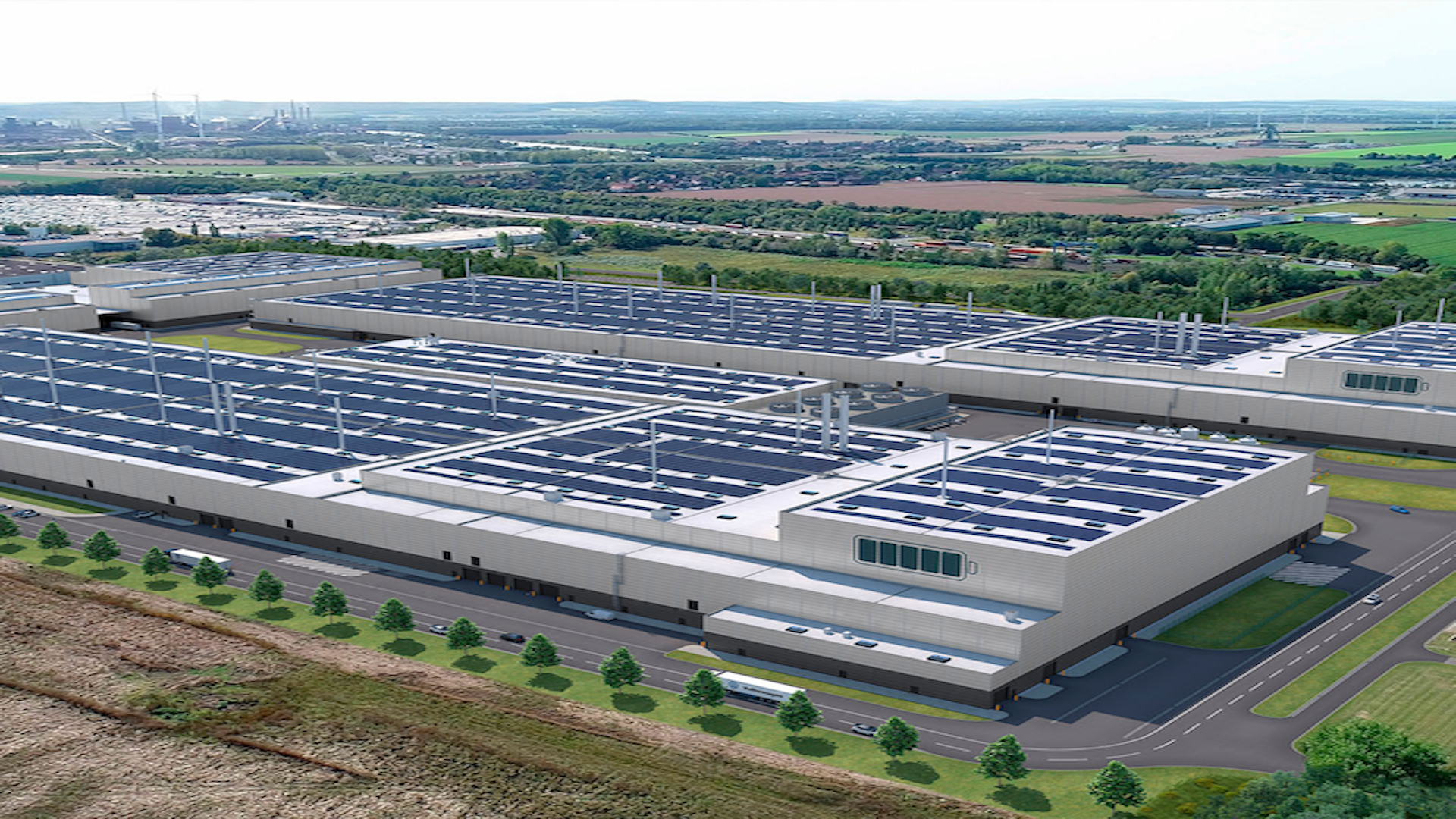

The Volkswagen Group is constructing its first gigafactory in Salzgitter as a battery center for electromobility, covering a total area of two million square meters. According to VW, the company aims to fully transition to electric mobility by 2030, with half of the required battery cells being produced in-house. In addition to the new gigafactory, adjacent existing buildings are being upgraded for the new usage concept.

One of the projects at the Volkswagen plant in Salzgitter includes converting Hall 4 into logistics areas (inbound and outbound) for the new battery cell factory. Originally built in 1970, the hall was previously used for the production, storage, and shipping of components for engine manufacturing. Due to this prior usage, the floors and other surfaces are contaminated, including with mineral oils. In the future, this area will serve as a warehouse for receiving, interim storage, and distribution of battery cell components from the new factory (inbound). The outbound area will be used to temporarily store and prepare the finished battery cells for shipping.

In Hall 4, DUCON provides a fully sealed and structurally reinforced overlay across an area of 28,200 m² with a load-bearing, reinforced concrete layer of only 40–55 mm. This approach eliminates the need for extensive demolition and remediation work, significantly reducing construction time and operational downtime to less than 30% of the typical duration.

Project Data:

- Construction period: 2025

- DUCON40 as jointless structural sealing and reinforcement

- Total area: approx. 28,200 m²

Feel free to contact us!

If you have further questions about DUCON Technology, we will gladly answer them by phone or email.

Germany & Europe

T +49 6151 30724-0

info@ducon.eu

North America

Phone: +1-212-498-7111

info@ducon-usa.com